Views: 0 Author: Site Editor Publish Time: 2025-11-25 Origin: Site

Jaw plates are essential components in a jaw crusher, playing a crucial role in breaking down materials by applying pressure and friction as the crusher’s jaw moves. The performance, operational efficiency, and longevity of your crusher heavily depend on selecting the right jaw plates. Using the appropriate jaw plates ensures that the crusher operates smoothly, reducing downtime and maintenance costs. The right choice also improves crushing efficiency and product consistency. This article will walk you through the key factors to consider when selecting jaw plates, the different types available, and provide helpful tips on maintaining them for optimal performance.

When choosing the right jaw plates for your crusher, it’s essential to first understand the different types of jaw plates available and how they are used.

Standard jaw plates are typically made of high manganese steel and are the most commonly used in general crushing operations. These plates are ideal for breaking down medium to hard materials such as rocks and ores. The high manganese content allows the plates to withstand wear and tear over time.

Applications: Suitable for standard crushing operations in various industries like mining, construction, and recycling.

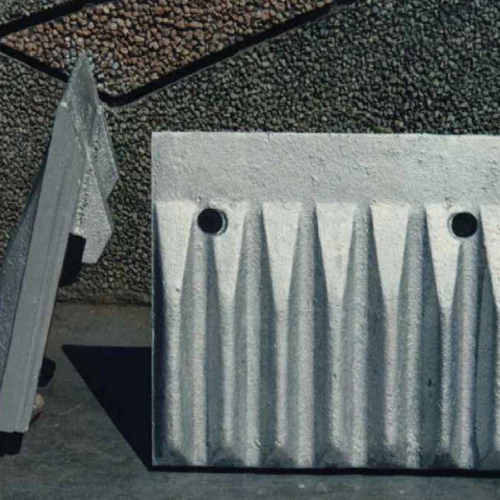

Heavy-duty jaw plates are designed for use in more aggressive crushing applications where tougher materials are processed. These plates are often thicker and have a higher amount of manganese or additional alloying elements for enhanced wear resistance.

Applications: Ideal for challenging materials such as granite, basalt, and other hard, abrasive rocks.

Some operations require customized jaw plates designed to meet specific needs, such as dealing with unique materials or improving efficiency for particular tasks. These plates can be engineered for specific jaw crushers, and material compositions can be tailored based on the customer’s requirements.

Applications: Used in specialized industries or for specific materials that require more advanced crushing solutions.

The material of the jaw plates plays a significant role in their overall performance. Selecting the correct material depends on the hardness, abrasiveness, and properties of the material being crushed. Below are the most common materials used in jaw plates.

Manganese steel is the most common material used for jaw plates. It is highly resistant to wear and has excellent shock-absorbing properties. Manganese steel can handle high-impact crushing applications and works well with hard materials.

Advantages:

High wear resistance

Durability under high-impact conditions

Good adaptability to high hardness materials

Ideal for: Crushing hard rocks and ores like granite, iron ore, and quartz.

In some cases, high-alloy steels may be used for jaw plates. These steels provide additional toughness and can handle more severe conditions than regular manganese steel.

Advantages:

Increased toughness and resistance to cracking

Better performance in high-pressure and high-temperature environments

Ideal for: Extreme crushing applications, where the jaw plates are exposed to continuous high pressure.

Emerging materials such as ceramic composites are used in specialized applications where conventional jaw plates may wear out too quickly. These materials offer unique benefits such as improved hardness and resistance to abrasions.

Advantages:

Extremely high wear resistance

Reduced frequency of replacements

Ideal for: Specialized industries, including recycling and cement manufacturing.

Choosing the right jaw plates requires a careful evaluation of various factors. Below are the key considerations that can help you make an informed decision.

One of the primary factors to consider when selecting jaw plates is the type and hardnessof the material you are crushing. Harder materials require jaw plates made of tougher, more durable materials. If your crusher processes softer materials, standard manganese plates might suffice.

Soft Materials: Standard manganese plates.

Harder Materials: Heavy-duty jaw plates or high-alloy steel plates.

The operating conditions of your crusher, such as temperature and pressure, also affect the choice of jaw plates. For crushers that operate in extreme environments (e.g., high-temperature crushing), high-alloy steel plates may be more appropriate.

High Temperature and Pressure: High-alloy steel or specialized materials.

Normal Conditions: Manganese steel or standard jaw plates.

Durability and wear resistance are essential factors in selecting jaw plates. While higher-quality materials may come with a higher upfront cost, they can result in lower maintenance costs and longer service life over time.

Short-Term Use: Lower-cost plates, though frequent replacement may be required.

Long-Term Use: Premium jaw plates designed for durability and high wear resistance.

The design of jaw plates directly influences the size of the crushed output material and the crusher's overall throughput. If you require a finer output or need to process larger volumes, you may need to adjust your jaw plate selection accordingly.

Output Size | Jaw Plate Type | Recommended Material |

Small (Fine Crush) | Standard Jaw Plates | Manganese Steel |

Medium (General Crush) | Heavy Duty Jaw Plates | High-Alloy Steel |

Large (Coarse Crush) | Specialized Jaw Plates | Ceramic, Composite Materials |

Once you’ve selected the right jaw plates, maintaining them properly is essential to ensuring maximum performance and longevity.

Inspect your jaw plates regularly to check for wear and tear. Early detection of wear can prevent unexpected breakdowns and allow for timely replacement of the plates.

Inspection Tips: Monitor for uneven wear, cracks, and significant reduction in plate thickness.

It’s essential to replace jaw plates when they are worn out to a point where they can no longer perform effectively. Some signs that your jaw plates need replacing include:

Excessive wear: Visible thinning or large cracks in the jaw plates.

Poor crushing performance: Lower throughput or inconsistent output size.

To prolong the life of your jaw plates, ensure proper maintenance procedures are followed. This includes lubrication, adjusting jaw plate settings, and keeping your crusher clean and free from debris.

Best Practices:

Regular lubrication to minimize friction.

Proper jaw plate adjustment to prevent unnecessary strain.

Keep the crushing chamber clean.

While the upfront cost of jaw plates is an essential consideration, quality should not be compromised for the sake of saving money. High-quality jaw plates often result in better performance, less downtime, and lower replacement costs in the long run.

Balancing Cost and Quality:

High-quality plates may cost more initially, but their longevity and performance will ultimately save you money by reducing operational disruptions.

Lower-cost plates may require more frequent replacements, increasing long-term operational costs.

Choosing the right jaw plates for your crusher is crucial for optimizing your operations and achieving both efficiency and cost-effectiveness. By carefully considering the material composition of the plates, the hardness of the materials being crushed, and the specific operating conditions of your crusher, you can make an informed choice that will enhance performance and reduce long-term costs.

When selecting jaw plates, ensure that the material and design are well-matched to the properties of the materials you’re crushing and your crusher’s operating environment. This can help maximize wear resistance, reduce maintenance, and extend the lifespan of your equipment.

For the best results, always factor in the long-term costs, including wear and tear, when making your selection. Whether you need standard, heavy-duty, or custom jaw plates, choosing the right fit can make a significant difference in your crusher’s efficiency and overall operating costs.

If you’re looking for expert advice or tailored solutions, consider reaching out to a trusted provider like KCY. Their team can help you select the right jaw plates and provide support to optimize your crushing operations.

A1: Jaw plates should be replaced when you notice a decline in crushing performance, visible wear, or cracks in the plates. Regular inspection can help detect these issues early.

A2: It’s not advisable to use the same jaw plates for all materials. The material being crushed (hardness, abrasiveness) influences the choice of jaw plate material and design.

A3: Manganese steel is commonly used for hard rock applications, but high-alloy steels may be necessary for extremely tough and abrasive materials.

A4: The lifespan of jaw plates depends on factors like the material being crushed, operational conditions, and maintenance practices. Proper maintenance can extend their lifespan significantly.

A5: Custom jaw plates can be worth the investment if your crushing needs are specialized. They ensure the optimal performance of your crusher and can reduce wear, saving costs in the long run.